In

AT-200

☰

filters

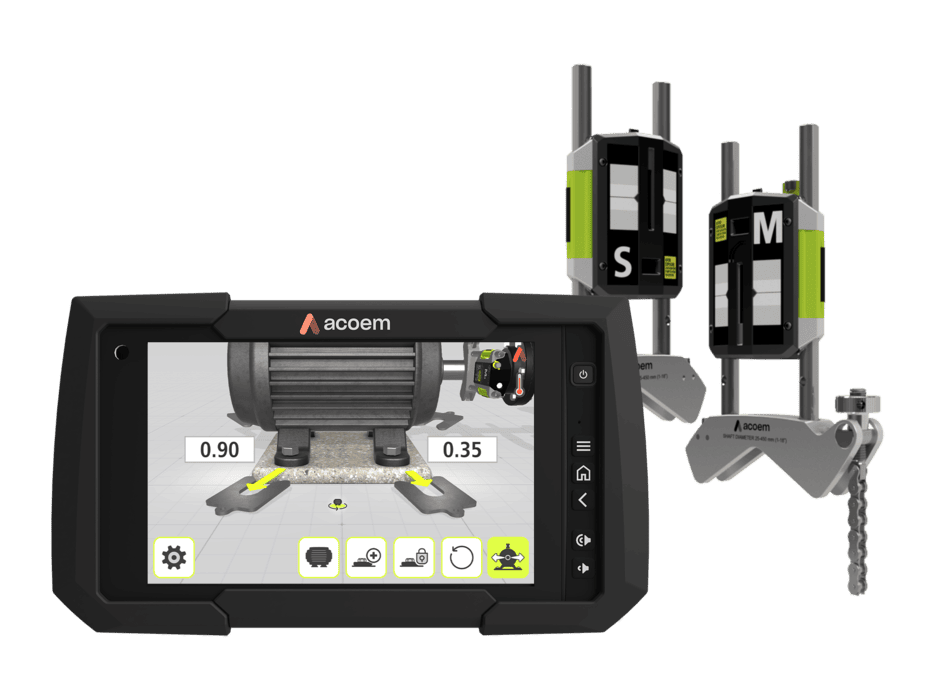

AT-200 – The smart app-based shaft alignment solution

This new generation of horizontal & vertical laser shaft alignment solution is the result of almost 40 years of expertise and innovation. Integrated apps, customized technology features and easy connectivity : the AT-200 leverages technology to enhance your user experience and improve the efficiency of your maintenance teams. Providing unparalleled measurement performance and fast, precision alignment, the AT-200 improve measurement and reporting capabilities, to help you extend every critical machinery’s lifespan.

Features

Digital sensor detectors Large 30 mm digital sensor detectors – capacity to handle long measurement distances and large angular misalignment errors | SoftCheck™ – Soft foot detector Easily verify the presence of soft foot to make a reliable alignment | FeetLock™ – Automatic guidance Get better automatic guidance for a base-bound or bolt-bound situation |

VertiZontal™ – Align machines in one move Align machines in horizontal and vertical direction in only one move and save time | Tolerances – Automatic quality assessment Automatic alignment quality assessment according to Tolerances based on industry standards | GuideU™ – Intuitive 3D graphical user interface Easily align your rotating assets following the highly visual Acoem GuideU™ interface |

True Live™ – Real time positioning Get the position of both the shafts in real time with Acoem True Live™ feature | Sensor technology – Remove disturbance Remove industrial environment disturbance (light, vibration) with the smart digital filtering provided with our sensor technology | The spacer shaft – Coupling function Used when the alignment is performed on machinery using membrane coupling |

Target values – Cold and Hot alignment (optional) Easily Manage thermal growth with Cold and Hot alignment |