Vibration sensors with 4-20 mA output and their application in machine diagnostics

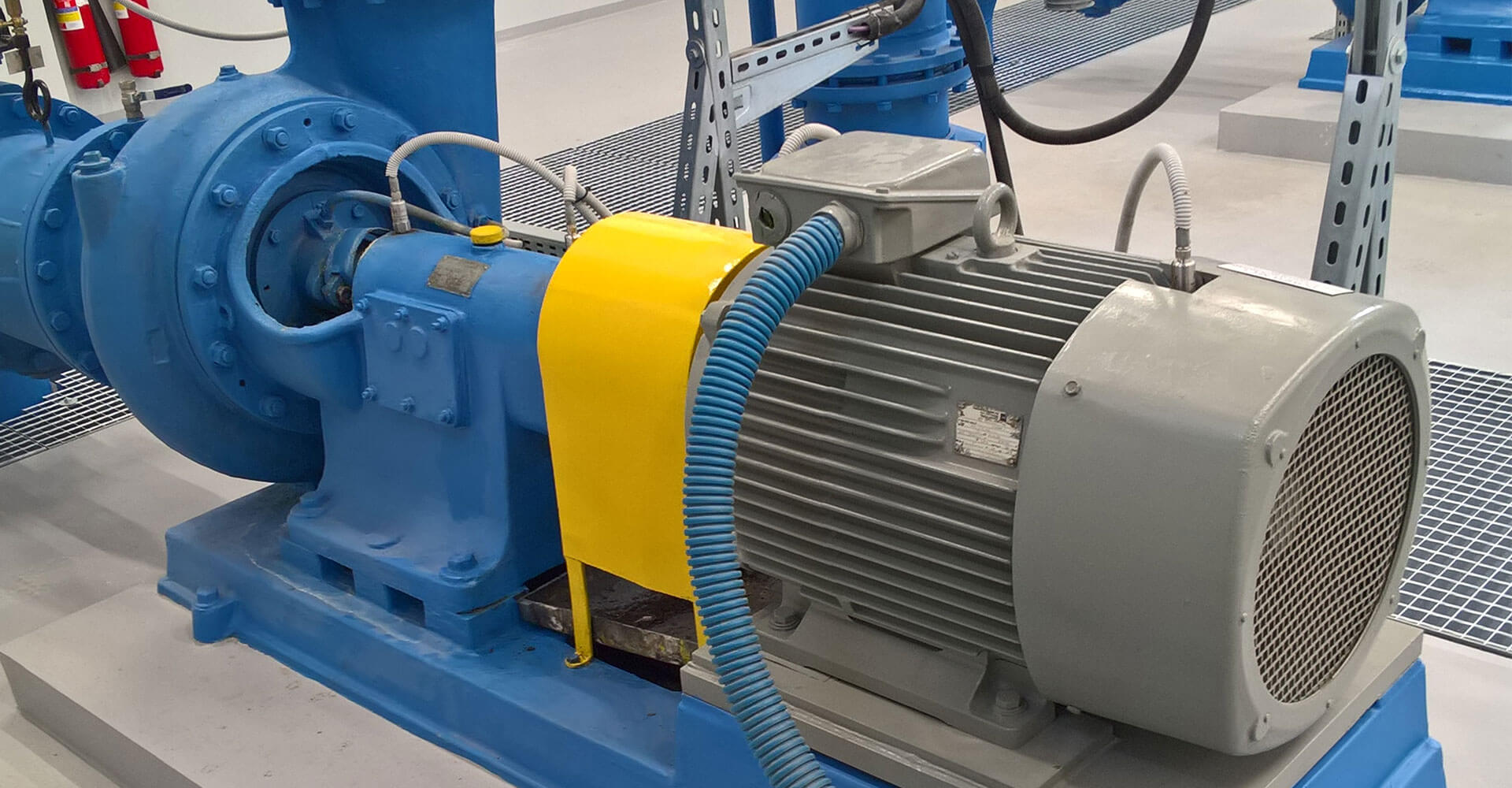

Vibration sensors with 4-20 mA output are used to monitor vibration and oscillation in industrial machinery and equipment.

The output of this type of sensor is a DC current ranging from 4 mA to 20 mA, which is proportional to the level of vibration detected by the sensor. Below is the key information on this subject:

- Current output: A vibration sensor with a 4-20 mA output generates a current signal instead of a voltage signal. The current range is 4 mA to 20 mA, meaning that the minimum current value is 4 mA in the absence of vibration, and the maximum value is 20 mA in the case of large vibration or failure.

- Proportionality: the output signal from the sensor is proportional to the amplitude or intensity of the vibration that is detected by the sensor. In practice, this means that larger vibrations result in a higher output current.

4..20 mA vibration sensors in machine vibration monitoring

Vibration sensors make it possible to detect and monitor vibrations and changes in the mechanical behavior of equipment. Here are some of the main aspects of using these sensors in machine diagnostics:

- Condition monitoring: Vibration sensors with 4-20 mA output enable continuous monitoring of machine vibration. These sensors measure the amplitude of vibration over a fixed frequency range, parameters that can indicate problems with the equipment.

- Fault diagnosis: By regularly monitoring machine vibration, early signs of failure can be detected. Changes in vibration levels, such as an increase in vibration amplitude, can indicate a problem that needs attention.

- Trends and data analysis: Data from vibration sensors can be collected and analyzed to create trends. This allows predicting future failures and planning machine maintenance.

- Malfunction detection: Vibration sensors are an effective tool for detecting malfunctions such as unbalance, clearances, bearing damage, structural damage and rotors

- Preventing failures: Vibration monitoring makes it possible to prevent failures by responding quickly to machine irregularities. Alarm levels can be set that alert personnel to intervene.

- Integration with control systems: Vibration sensor signals with 4-20 mA output can be easily integrated into machine control and monitoring systems. This allows remote monitoring of emerging symptoms of machine failures.

- Reduced maintenance costs: By detecting problems early and scheduling maintenance, emergency repair costs can be reduced and the life of machines can be extended.

- Sensor calibration and maintenance: It is important to calibrate and maintain vibration sensors regularly to ensure the accuracy of measurements and the reliability of the diagnostic system.

Summary

Vibration sensors with 4-20 mA output are often used because of their simplicity and compatibility with existing industrial systems. However, there are also more advanced diagnostic technologies, such as vibration spectral analysis, that allow for even more advanced machine diagnostics. It is worth considering which solution best suits your company’s needs and resources.